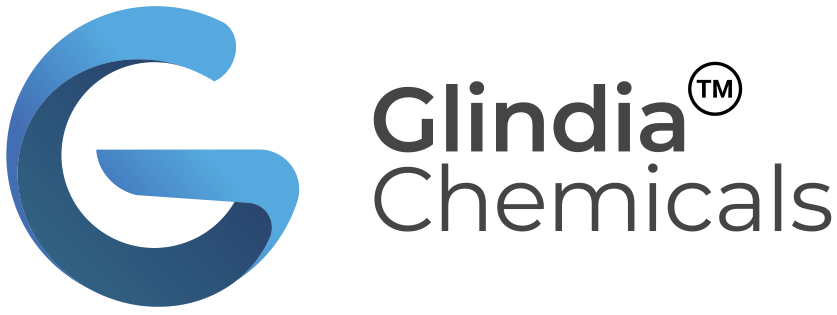

Introduction to Trimethylchlorosilane (TMCS):

Trimethylchlorosilane, often abbreviated as TMCS, is an organosilicon compound with the chemical formula (CH3)3SiCl. It is a colorless, volatile liquid with a sharp, pungent odor. TMCS is widely recognized for its role as a versatile reagent in surface modification, functionalization, and synthesis processes.

Formula:

C3H9SiCl

Synonyms:

- Trimethylsilyl chloride

- Chlorotrimethylsilane

- TMCS

- Monochlorotrimethylsilicon

- Chloro(trimethyl)silane

Properties of TMCS:

- Chemical Structure : HMDS features two silicon atoms bonded to three methyl groups and one imino group each, imparting unique chemical properties.

- Physical State : HMDS is typically found in liquid form at room temperature, with a boiling point of approximately 126°C.

- Reactivity : HMDS is highly reactive due to the presence of silicon-nitrogen bonds, making it suitable for surface modification and functionalization.

- Hydrophobicity : HMDS-treated surfaces exhibit excellent hydrophobic properties, repelling water and other polar substances effectively.

Applications of TMCS:

TMCS is widely employed in surface modification processes to enhance the hydrophobicity and chemical resistance of various substrates. It forms self-assembled monolayers (SAMs) on surfaces, providing a tailored interface for subsequent functionalization or adhesion processes.

TMCS serves as a precursor in CVD processes for depositing silicon-containing thin films onto substrates. These films find applications in microelectronics, photovoltaics, and protective coatings.

TMCS is utilized in organic synthesis reactions as a silylating agent for introducing trimethylsilyl (TMS) groups into organic molecules. This silylation process enhances compound volatility, stability, and derivatization capabilities.

TMCS-treated surfaces serve as platforms for immobilizing catalysts and ligands in heterogeneous catalysis reactions, facilitating efficient chemical transformations and product separations.

TMCS is a key intermediate in the production of silicone rubber, where it is utilized as a crosslinking agent to impart elasticity, durability, and heat resistance to the final product.

TMCS is employed in GC analysis as a derivatization reagent for enhancing the volatility and detectability of polar compounds prior to separation and detection.

Benefits of TMCS:

Versatility

TMCS offers versatility in surface modification, synthesis, and catalysis applications, providing tailored solutions for diverse industrial and research needs.

Enhanced Performance

TMCS-treated surfaces exhibit improved properties such as hydrophobicity, chemical resistance, and adhesion, leading to enhanced performance and durability.

Precision

TMCS enables precise control over surface functionalization and molecular modification, allowing for fine-tuning of material properties and surface interactions.

Cost-Effectiveness

TMCS-based processes offer cost-effective solutions for surface modification and synthesis compared to alternative methods, thereby optimizing production processes and reducing overall manufacturing costs.

Compatibility

TMCS is compatible with a wide range of substrates and materials, ensuring seamless integration into existing manufacturing processes.

Safety Considerations:

While TMCS is a valuable chemical reagent, it should be handled with care due to its reactive nature. Key safety considerations include:

TMCS should be used in a well-ventilated area to prevent inhalation of vapors.

Personal protective equipment such as gloves, goggles, and lab coats should be worn when handling TMCS to prevent skin contact and eye irritation.

TMCS should be stored in a cool, dry place away from direct sunlight and incompatible materials.

In case of spillage, absorbent materials should be used to contain and clean up the spill, and appropriate disposal procedures should be followed.

Hexamethyldisilazane (HMDS) is a versatile chemical compound with numerous applications in surface modification across various industries. Its unique properties, coupled with its ease of application and cost-effectiveness, make it an indispensable tool for enhancing the performance and functionality of diverse materials and substrates. However, proper handling and safety precautions must be observed to ensure safe use in industrial and laboratory settings.